Hazardous waste management is crucial for industrial facilities to protect the environment and employee health. It involves understanding diverse substances like toxic chemicals, radioactivity, biological organisms, and electronic waste, and implementing strategies such as recycling, treatment, or off-site disposal. Best practices include securing containers, regular inspections, employee training with PPE, and adhering to regulations. Innovative technologies like bio-remediation and AI-enhanced sorting systems streamline waste reduction, increase recycling rates, enhance safety, and reduce costs associated with environmental pollution.

Industrial facilities generate a wide range of hazardous wastes, posing significant environmental and health risks. This article explores comprehensive solutions for managing these challenges, focusing on understanding different types of hazardous waste, implementing best practices for safe storage and handling, and leveraging innovative technologies in waste minimization and disposal. Discover how proactive approaches can transform industrial operations into more sustainable and responsible enterprises through effective hazardous waste management.

- Understanding Hazardous Waste: Types and Impact

- Best Practices for Safe Storage and Handling

- Innovative Technologies in Waste Minimization and Disposal

Understanding Hazardous Waste: Types and Impact

Hazardous waste is any type of waste material that poses a significant risk to human health and the environment if not properly handled and disposed of. It includes a wide range of substances, from toxic chemicals and radioactive materials to biological organisms and certain types of electronic waste. Understanding these different categories and their potential impacts is crucial for effective hazardous waste management solutions within industrial facilities.

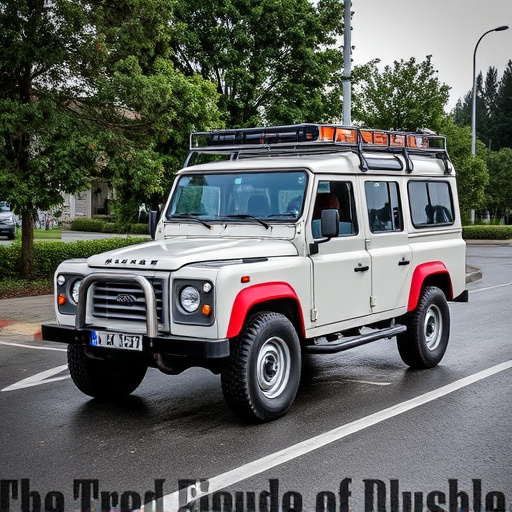

Industrial processes often generate various forms of hazardous waste, including toxic liquids, gases, and solids. For instance, car bodywork services and automotive restoration shops may produce hazardous waste from the use of solvents, paints, and other chemicals during vehicle repairs. These substances can contaminate soil, water bodies, and air if not collected, treated, and disposed of properly. Knowing these risks allows facilities to implement tailored strategies, such as recycling, treatment, or secure off-site disposal, ensuring compliance with regulations and minimizing the ecological footprint.

Best Practices for Safe Storage and Handling

Implementing best practices for the safe storage and handling of hazardous waste is paramount for industrial facilities to uphold environmental stewardship and employee safety. This involves securing containers with robust, leak-proof lids and storing them in designated areas away from direct sunlight, heat sources, and incompatible substances. Regular inspections and maintenance checks are crucial to ensure containers remain intact and conform to regulatory standards.

Training employees on proper handling techniques, including the use of personal protective equipment (PPE), is essential. This prevents accidental exposure and ensures compliance with hazardous waste management protocols. By adhering to these practices, industrial facilities can effectively manage their waste streams, mitigating risks and promoting a sustainable future—a far cry from the challenges faced in sectors like automotive body work or even mercedes benz collision repair, where safety and precision are paramount but with very different hazard profiles.

Innovative Technologies in Waste Minimization and Disposal

In the realm of hazardous waste management, innovative technologies are revolutionizing industrial facilities’ approach to waste minimization and disposal. Advanced processes such as bio-remediation, where microorganisms are employed to break down toxic substances, offer eco-friendly alternatives to traditional methods. Additionally, automated sorting systems equipped with artificial intelligence can precisely categorize recyclables and hazardous materials, enhancing recycling rates and ensuring safer handling.

These cutting-edge solutions not only streamline waste management but also contribute to cost savings for industrial operations. For instance, implementing advanced treatment technologies for water waste can reduce the need for extensive car damage repair or automotive body work by minimizing pollution and preserving the environment. Similarly, efficient waste sorting and recycling practices can divert materials from landfills, preventing the need for frequent car restoration efforts due to limited resources.

Effective hazardous waste management is crucial for industrial facilities to minimize environmental impact and ensure worker safety. By understanding different types of hazardous waste, implementing best practices for storage and handling, and embracing innovative technologies in waste minimization and disposal, industries can navigate the challenges of managing these materials responsibly. Integrating these strategies into operational workflows fosters a culture of sustainability and compliance, contributing to a cleaner, safer future for both communities and the planet.