Advanced sensors and real-time monitoring, remote-controlled robots, and data analytics revolutionize hazardous waste management, enhancing safety and efficiency in handling toxic substances, from collision repair to tire services. These technologies improve precision, reduce environmental impact, and prioritize worker well-being, transforming the field of hazardous waste management for a cleaner, more sustainable future.

In the realm of hazardous waste management, innovation plays a pivotal role in ensuring safety and environmental preservation. Today’s advanced tools equip professionals with unprecedented capabilities. From real-time monitoring through sophisticated sensors to remote-controlled robots taking on dangerous tasks, these technologies enhance efficiency and mitigate risks. Data analytics further revolutionize the field by enabling predictive waste tracking and minimization strategies. This article explores these cutting-edge solutions that are reshaping hazardous waste management practices globally.

- Advanced Sensors and Real-Time Monitoring

- Remote-Controlled Robots for Dangerous Tasks

- Data Analytics: Predictive Waste Tracking and Minimization

Advanced Sensors and Real-Time Monitoring

In the realm of hazardous waste management, advanced sensors and real-time monitoring have emerged as indispensable tools. These innovative technologies play a pivotal role in enhancing safety and efficiency during the handling and disposal of harmful substances. By deploying sophisticated sensors, professionals can accurately detect and measure various parameters such as gas concentrations, temperature, and moisture levels at toxic sites. This real-time data enables swift decision-making and proactive measures to mitigate potential risks.

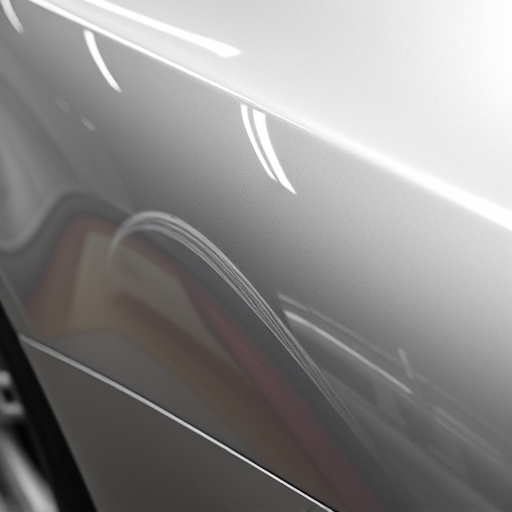

Unlike traditional methods that rely on periodic testing, these modern sensors provide continuous monitoring, ensuring that any deviations or anomalies are immediately flagged. This capability is particularly crucial for hazardous waste management, where timely intervention can prevent accidents and minimize environmental impact. Moreover, the integration of such technology with vehicle repair services specializing in mercedes benz collision repair showcases a broader application. Auto repair near me facilities equipped with advanced sensors not only enhance their safety protocols but also contribute to sustainable practices by accurately managing hazardous materials encountered during restoration processes.

Remote-Controlled Robots for Dangerous Tasks

In the realm of hazardous waste management, remote-controlled robots are transforming dangerous tasks into safer operations. These advanced machines are equipped with sophisticated sensors and cameras, allowing them to navigate complex environments while minimizing human exposure to harmful substances. By remotely operating these bots, waste management teams can handle toxic materials, disassemble contaminated structures, and even clean up spills without putting workers at risk. This technology is a game-changer, especially in industries like collision repair centers and auto body repairs, where handling hazardous chemicals is common.

Remote-controlled robots offer precision and efficiency, ensuring that every movement is calculated to avoid accidents. They can be deployed in situations where the presence of humans could lead to collisions or exposure to dangerous gases, liquids, or particles. With their versatility, these robots are not limited to hazardous waste management; they also find applications in scratch repairs and auto body repairs, providing a safer alternative for technicians while maintaining high-quality work standards.

Data Analytics: Predictive Waste Tracking and Minimization

In the realm of hazardous waste management, data analytics stands out as a game-changer, offering predictive capabilities that revolutionize waste tracking and minimization efforts. By leveraging advanced algorithms, this technology enables professionals to anticipate and prevent potential risks associated with waste disposal. Through the analysis of historical data, patterns can be identified, allowing for more precise predictions about the types, quantities, and locations of hazardous materials. This proactive approach ensures that waste is managed efficiently, reducing environmental impact and safety hazards.

Furthermore, predictive analytics aids in optimizing collection routes, scheduling, and resource allocation. Just as it benefits other sectors with optimized logistics, this technology helps waste management companies streamline their operations, especially when considering services like car scratch repair and tire services, which often generate hazardous byproducts. By minimizing waste at the source, these innovative tools contribute to a cleaner, safer environment, ultimately supporting the broader goal of sustainable hazardous waste management practices.

The innovative tools discussed—advanced sensors, remote-controlled robots, and data analytics—represent significant advancements in hazardous waste management. By leveraging real-time monitoring, automated dangerous tasks, and predictive tracking, these technologies not only enhance safety for personnel but also contribute to more efficient waste minimization strategies. As these solutions continue to evolve, their integration into waste management practices will be pivotal for creating a safer, more sustainable future.